YRT turntable bearing:

Classification :

Keywords:

Cross roller bearing

YRT turntable bearing:

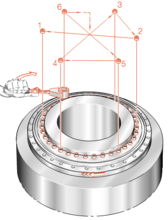

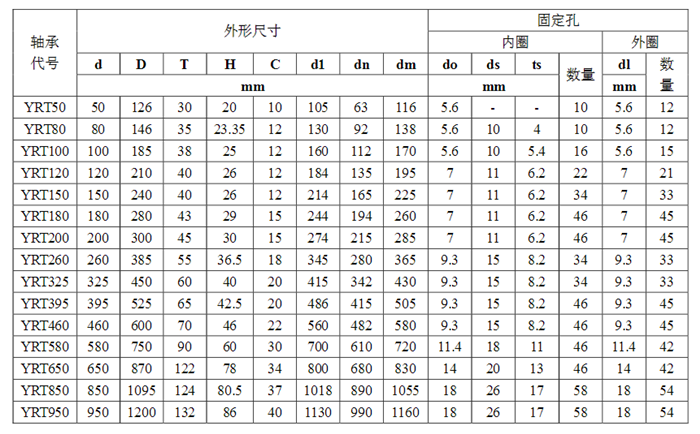

Turntable bearing is a kind of rotary mechanism with outer ring rotation and internal support. It is mainly divided into three series: YRT type, YRTS type, and YRTM type. These three series of oil bearings have the same installation size, different internal structure, and similar performance.YRT series bearings are composed of three rows of rollers, two rows of axial rollers to ensure stable axial carrying capacity, and one row of radial rollers to ensure that the bearing can withstand radial force and overturning torque, suitable for axial bearing rotary mechanism.YRT turntable bearings are mainly used in CNC machine tool manufacturing.

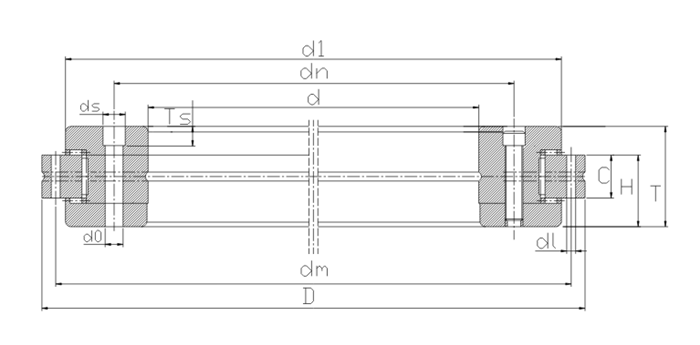

The YRT turntable bearing consists of a thrust/centripetal shaft ring, a thrust washer, two needle roller cage assemblies and a set of centripetal round rollers.The seat ring and shaft ring have evenly distributed screw holes for installation.This type of pumping bearing has high axial and warp carrying capacity.High tilt stiffness and extremely high accuracy.Suitable for rotary tables, chucks and milling cutter heads, as well as bearing configurations in measurements and experiments.This type of bearing also has higher requirements for matching equipment parts.During installation, the tightening torque of the mounting screws needs to be controlled.

Scope of application: It is widely used in precision rotary tables, CNC rotary tables, vertical grinding machines, indexing heads, gear hobbing machines, gear milling machine workpiece shafts and other precision devices.

YRT turntable bearing mounting part:

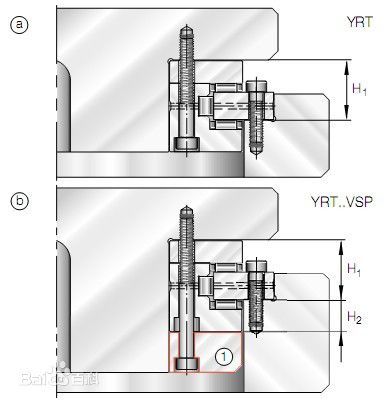

1.The requirements for the mating structure are shown in the figure on the right. The fixing screws protect the bearing parts during transportation. In order to make it easier to install the centering, the fixing screws can be loosened during installation. After installation, the fixing screws should be tightened again or the fixing screws replaced with positioning screws.

2.L-section ring 2 can be installed with or without additional support ring

a) Without support ring, bearing code YRT

b) If the L-section ring is used to support the ring, the bearing code is TRT...VSP, and the entire surface of the L-section ring must be supported 3.The assembly force can only be transmitted through the installed bearing ferrule, and must not be transmitted through the rolling element.

4.The positioning screw is tightened with a torque wrench in the form of a cross (see Figure 2).

5.Do not separate or exchange bearing parts for installation and disassembly.

6.The starting friction torque is 3~3.5 times that of the bearing friction torque listed in the size table.

RELATED PRODUCTS

GET A FREE QUOTE