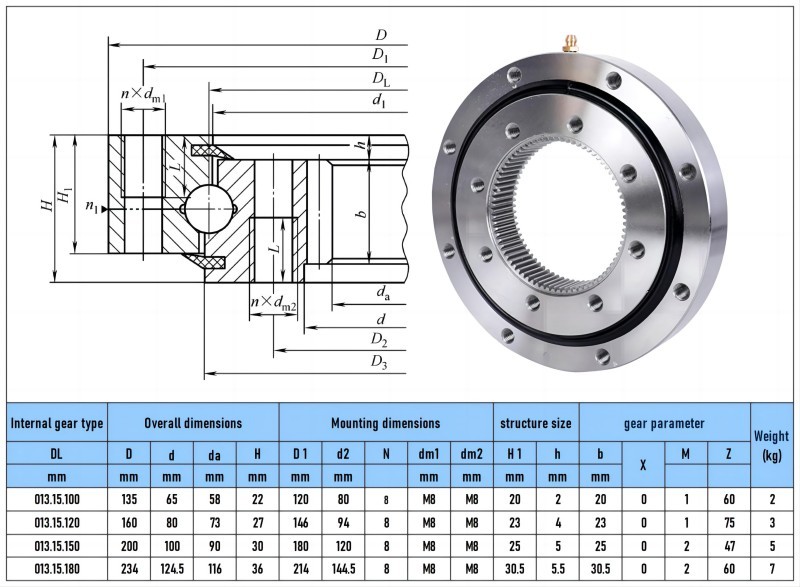

Slewing bearing (internal tooth type)

Classification :

Keywords:

Slewing bearing

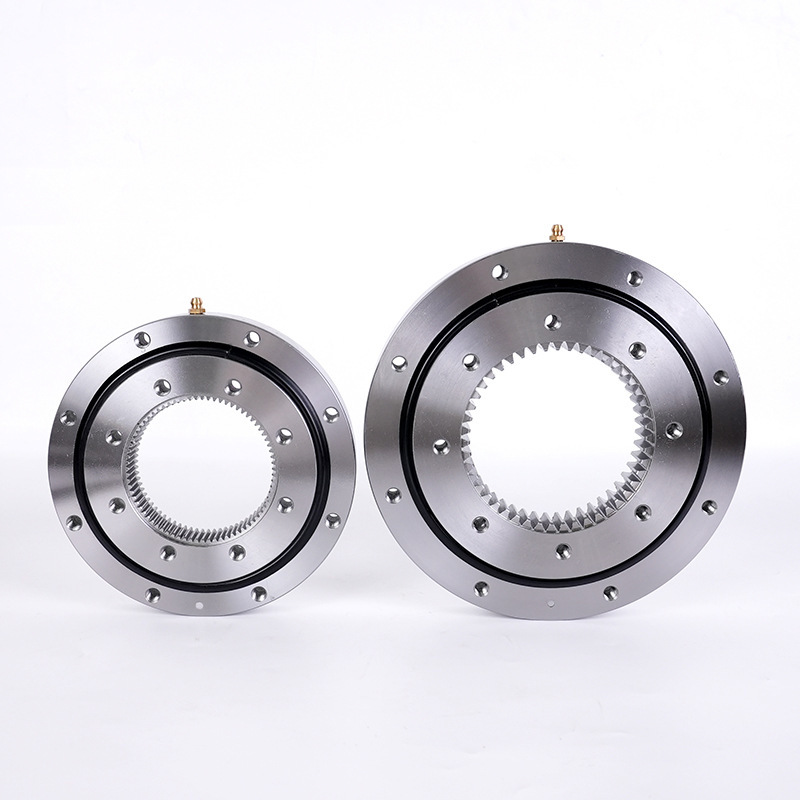

Small size internal tooth type slewing bearing bearing

Professionally customized for customers,

The inner and outer gears of the slewing ring are directly toothed on the inner or outer ring, and are processed by a gear hobbing machine or a gear shaper. If the working environment is loaded, it needs to be quenched. The internal gear slewing ring: the overall appearance is relatively neat, There is no need to install a safety cover at the meshing part of the gear and the slewing ring. The gear has better dust resistance, longer retention time by adding lubricant, and lower transmission contact stress of internal gear meshing, less wear and longer service life.

If it is an internal gear type, the outer gear ring should be fixed with bolts of appropriate strength grade. The bolts and nuts should meet the standards of GB3098.1 and GB3098.2. Then the pinion gears mesh with the inner teeth to drive the inner ring to rotate to achieve the purpose of transmission.

One of the most common applications is excavators. Generally, excavators need to use internal tooth slewing bearings, and the internal teeth need to be quenched to increase the hardness of the teeth.

Slewing bearing is a kind of large bearing that can withstand comprehensive loads, and can withstand large axial and radial loads and overturning moments at the same time.

Slewing bearings are widely used in real industry. They are called "joints of machines". They are important transmission components necessary for machinery that needs to make relative rotary movement between two objects and withstand axial force, radial force, and overturning torque at the same time.With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, construction machinery, light industry machinery, metallurgical machinery, medical machinery, industrial machinery and other industries.

RELATED PRODUCTS

GET A FREE QUOTE