YRT to the bearing

Classification :

Keywords:

YRT to the bearing

YRT's bearing is composed of a thrust/to the heart axis, a thrust pad, and two roller stitches. The rim and axis are installed with screw holes with averaged cloth. This type of bearing has high axial and radial bearing capacity. High tilt rigidity and extremely high accuracy. Suitable for the bearing configuration of the turning workbench, card and milling cutter, and measurement and experiments. This type of bearings also requires higher requirements for equipment parts that matches it. When installing, you need to control the tight torque of the installation screw.

Scope of application: It is widely used in precision devices such as the precision rotating platform grinding machine, division head, teeth machine, and milling machine workpiece shaft.

YRT Standard Series

Planted — A combination of the centrifuge can withstand the two -way axial load, radial load and overturned torque at the same time. There are installation holes on the bearing, which can be used to directly fix the bearing with bolts; the bearings have been pre -loaded when the factory is left, and the installation does not need to adjust the gap. A high occasion, such as turning in the workbench, division head, etc.

With rich product lines, in addition to the rich product line, in addition to the standard series of low -speed and short -term applications, we also provide corresponding products and solutions for more applications. High -speed series can be used for low -friction torque and relatively high -speed occasions. It is applicable to the bearing selection of directly drive the motor conversion and the double -swing milling head. The thrust angle contact ball series has the characteristics of high -speed, low friction torque, and can also withstand a combination load. It is suitable for high -speed rotation workbenches in the field of turning and milling and processing, and high -speed rotation workbench in the field of measurement and control. The series of rotary bearing with an integrated angle measurement system measures the modular design of the system through an integrated angle, and realizes the integrated accurate rotation and accurate angle control of the turntable. The structure is simplified. Condition.

YRT to the bearing model parameter

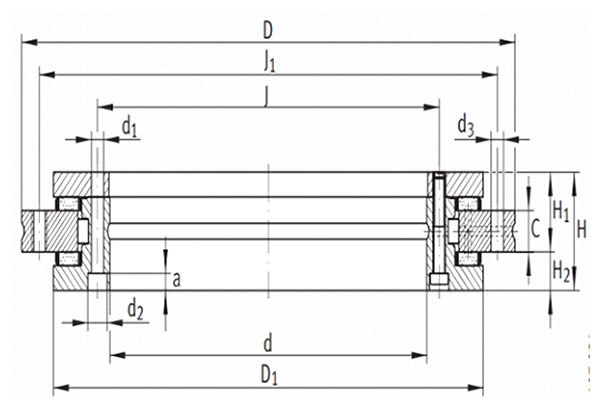

| Bearing Type | Dimension | The fixing holes | |||||||||||||

| d | D | H | H1 | H2 | C | d1 | dn | dm | Inner ring | Outer ring | |||||

| unit:mm | do | ds | Ts | quantity | dL | QTY | |||||||||

| Unit:mm | mm | QTY | mm | ||||||||||||

| YRT50 | 50 | 126 | 30 | 20 | 10 | 10 | 105 | 63 | 116 | 5.6 | 9 | 4.2 | 10 | 5.6 | 12 |

| YRT80 | 80 | 146 | 35 | 23.35 | 11.65 | 12 | 130 | 92 | 138 | 5.6 | 10 | 4.2 | 10 | 4.6 | 12 |

| YRT100 | 100 | 185 | 38 | 25 | 13 | 12 | 160 | 112 | 170 | 5.6 | 10 | 5.4 | 16 | 5.6 | 15 |

| YRT120 | 120 | 210 | 40 | 26 | 14 | 12 | 184 | 135 | 195 | 7 | 11 | 6.2 | 22 | 7 | 21 |

| YRT150 | 150 | 240 | 40 | 26 | 14 | 12 | 214 | 165 | 225 | 7 | 11 | 6.2 | 34 | 7 | 33 |

| YRT180 | 180 | 280 | 43 | 29 | 14 | 15 | 244 | 194 | 260 | 7 | 11 | 6.2 | 46 | 7 | 45 |

| YRT200 | 200 | 300 | 45 | 30 | 15 | 15 | 274 | 215 | 285 | 7 | 11 | 6.2 | 46 | 7 | 45 |

| YRT260 | 260 | 385 | 55 | 36.5 | 18.5 | 18 | 345 | 280 | 365 | 9.3 | 15 | 8.2 | 34 | 9.3 | 33 |

| YRT325 | 325 | 450 | 60 | 40 | 20 | 20 | 415 | 342 | 430 | 9.3 | 15 | 8.2 | 34 | 9.3 | 33 |

| YRT395 | 395 | 525 | 65 | 42.5 | 22.5 | 20 | 486 | 415 | 505 | 9.3 | 15 | 8.2 | 46 | 9.3 | 45 |

| YRT460 | 460 | 600 | 70 | 46 | 24 | 22 | 560 | 482 | 580 | 10 | 15 | 8.2 | 46 | 10 | 45 |

| YRT580 | 580 | 750 | 90 | 60 | 30 | 30 | 700 | 610 | 720 | 11.4 | 18 | 11 | 46 | 11.4 | 42 |

| YRT650 | 650 | 870 | 122 | 78 | 44 | 34 | 800 | 680 | 830 | 14 | 20 | 13 | 45 | 14 | 42 |

| YRT850 | 850 | 1095 | 124 | 80.5 | 43.5 | 37 | 1018 | 690 | 1055 | 18.5 | 26 | 17 | 57 | 18.5 | 54 |

| YRT950 | 950 | 1200 | 132 | 86 | 46 | 40 | 1130 | 990 | 1160 | 18.5 | 26 | 17 | 57 | 18.5 | 54 |

| YRT1030 | 1030 | 1300 | 145 | 92.5 | 52.5 | 40 | 1215 | 1075 | 1255 | 18.5 | 26 | 17 | 66 | 18.5 | 66 |

| YRT1200 | 1200 | 1490 | 164 | 108 | 56 | 52 | 1410 | 1240 | 1445 | 18.5 | 26 | 17 | 66 | 18.5 | 66 |

| Screw connection QTY | Connect screws holes | Pitch t | Tightening torque of screw | Basic rated load | Limited spped | Friction moment | Weight | Type | ||||

| Axial | Radial | |||||||||||

| Dynamic | Static | Dynamic | Static | |||||||||

| MA2) | Ca | Coa | Cr | Cor | Lubricating | |||||||

| Grease Lubrication | ||||||||||||

| G | QTY | Xt QTY Xt | Nm | kN | r/min | Nm | ≈Kg | |||||

| 2 | — | — | 12×30° | 8.5 | 38 | 158 | 28.5 | 49.5 | 600 | 2.5 | 1.6 | YRT50 |

| 2 | — | — | 12×30° | 8.5 | 56 | 255 | 42.5 | 100 | 530 | 3 | 2.4 | YRT80 |

| 2 | M5 | 3 | 18×20° | 8.5 | 76.5 | 415 | 47.5 | 120 | 430 | 3 | 4.1 | YRT100 |

| 2 | M8 | 3 | 24×15° | 14 | 102 | 540 | 52 | 143 | 340 | 7 | 5.3 | YRT120 |

| 2 | M8 | 3 | 36×10° | 14 | 112 | 630 | 56 | 170 | 320 | 10 | 6.2 | YRT150 |

| 2 | M8 | 3 | 48×7.5° | 14 | 118 | 710 | 69.5 | 200 | 280 | 12 | 7.7 | YRT180 |

| 2 | M8 | 3 | 48×7.5° | 14 | 120 | 765 | 81.5 | 220 | 260 | 14 | 9.7 | YRT200 |

| 2 | M12 | 3 | 36×10° | 34 | 160 | 1060 | 93 | 290 | 200 | 20 | 18.3 | YRT260 |

| 2 | M12 | 3 | 36×10° | 34 | 275 | 1930 | 120 | 345 | 170 | 40 | 25 | YRT325 |

| 2 | M12 | 3 | 48×7.5° | 34 | 300 | 2280 | 186 | 655 | 140 | 55 | 33 | YRT395 |

| 2 | M12 | 3 | 48×7.5° | 34 | 355 | 2800 | 200 | 765 | 120 | 70 | 45 | YRT460 |

| 2 | M12 | 6 | 48×7.5° | 68 | 490 | 4250 | 228 | 965 | 80 | 140 | 89 | YRT580 |

| 2 | M12 | 6 | 48×7.5° | 116 | 1040 | 8000 | 490 | 1800 | 65 | 200 | 170 | YRT650 |

| 3 | M16 | 6 | 60×6° | 284 | 1000 | 8650 | 455 | 1730 | 50 | 300 | 253 | YRT850 |

| 3 | M16 | 6 | 60×6° | 284 | 1290 | 11400 | 530 | 2040 | 40 | 600 | 312 | YRT950 |

| 6 | M16 | 6 | 72×5° | 284 | 1380 | 12000 | 620 | 2650 | 35 | 800 | 375 | YRT1030 |

| 6 | M16 | 6 | 72×5° | 284 | 1435 | 12850 | 745 | 2800 | 25 | 1000 | 450 | YRT |

RELATED PRODUCTS

GET A FREE QUOTE