Ultra -thin balls bearing

Classification :

Keywords:

Waiting for the section thin -walled series (British system)

Ultra -thin ball spherical bearing introduction

With the continuous development of technological progress, various new technology products have also entered everyone's daily life and work. In the field of precision machinery and equipment, its development trend has reached a new level. The influence of thin -walled bearings and the emergence of thin -walled bearings have also reached the peak of development trends in this field. The emergence of thin -walled bearings has promoted the development trend of precision machinery and equipment. It is worth mentioning that the economic development rights in this field have also emerged. Unusual benefits.

Ultra -thin ball spherical bearing realizes thin bearing cuts, and also realizes the miniaturization and lightweight of the product. The diversity of the product has extended its scope of use.

Ultra -thin ball bearing has the advantages of light quality, compact structure, and small inertial moment. It is widely used in high -end products such as industrial robots, aerial aircraft, aerospace satellites, and medical care, and the market size has gradually increased. However, the cross -sectional area of the thin -walled bearings makes its radial wall thick and poor, and it is very easy to produce large radial deformation. Therefore, in many processes such as turning, heat treatment, grinding processing, etc. In order to prevent defects such as ellipse, circular circles, and end surface warming and deformation, the bearing circle needs to be protected.

The industry covered by thin wall bearing is also common. The scientific research and technological development of thin -walled bearing manufacturers have benefited this field. The use value of thin wall bearings is unmatched by traditional bearing.

In terms of cost characteristics, thin -walled bearings are not only suitable for small parts of low -cost electrical equipment and furniture, but also common in the aerospace industry. The brand image of the product can be said to be ubiquitous. Instead, the traditional bearing of the previous traditional bearing was almost impossible to guarantee this.

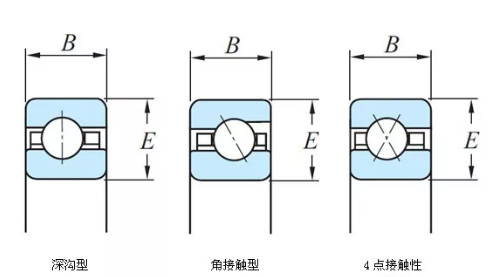

It belongs to ultra -thin wall type, which is both light and thin, making it widely used in industrial robots and other automated and efficient equipment. Such products are divided into series according to the cross section size. Regardless of the inner diameter, the cross -sectional size of the same series is the same.

Ultra -thin ball bearing model parameter

| Bearing | Size(mm) | Basic fixed load(N) | |||

| Inner diameter | outer diameter | width | Cr | Cor | |

| NB700 | 10 | 15 | 3 | 960 | 515 |

| 6800 | 10 | 19 | 5 | 1720 | 840 |

| 6900 | 10 | 22 | 6 | 1270 | 1270 |

| NB701 | 12 | 18 | 4 | 655 | 655 |

| 6801 | 12 | 21 | 5 | 1040 | 1040 |

| 6901 | 12 | 24 | 6 | 1460 | 1460 |

| NB702 | 15 | 21 | 4 | 800 | 800 |

| 6802 | 15 | 24 | 5 | 1260 | 1260 |

| 6902 | 15 | 28 | 7 | 2260 | 2260 |

| NB703 | 17 | 23 | 4 | 895 | 895 |

| 6803 | 17 | 26 | 5 | 1570 | 1570 |

| 6903 | 17 | 30 | 7 | 2550 | 2550 |

| NB704 | 20 | 27 | 4 | 1340 | 1340 |

| 6804 | 20 | 32 | 7 | 2470 | 2470 |

| 6904 | 20 | 37 | 9 | 3700 | 3700 |

| NB705 | 25 | 32 | 4 | 1650 | 1650 |

| 6805 | 25 | 37 | 7 | 3150 | 3150 |

| 6905 | 25 | 42 | 9 | 7050 | 4550 |

| NB706 | 30 | 37 | 4 | 2050 | 1950 |

| 6806 | 30 | 42 | 7 | 4700 | 3650 |

| 6906 | 30 | 47 | 9 | 7250 | 5000 |

| NB707 | 35 | 44 | 5 | 2810 | 2760 |

| 6807 | 35 | 47 | 7 | 4900 | 4100 |

| 6907 | 35 | 55 | 10 | 10600 | 7250 |

| NB708 | 40 | 50 | 6 | 3650 | 3600 |

| 6808 | 40 | 52 | 7 | 4900 | 4350 |

| 6908 | 40 | 62 | 12 | 13700 | 10000 |

| NB709 | 45 | 55 | 6 | 3800 | 4050 |

| 6809 | 45 | 58 | 7 | 5350 | 5250 |

| 6909 | 45 | 68 | 12 | 14100 | 10900 |

| NB710 | 50 | 62 | 6 | 5550 | 5750 |

| 6810 | 50 | 65 | 7 | 6400 | 6200 |

| 6910 | 50 | 72 | 12 | 14500 | 11700 |

RELATED PRODUCTS

GET A FREE QUOTE